Managing inventory effectively is very important for any business, whether you are a small retailer or a growing enterprise. With customer expectations increasing and supply chains becoming more complex, companies must understand how to track, control, and organise their stock with accuracy.

The purpose of the system is to reduce cost while smoothing the business operations, along with meeting customer expectations of demand

In this guide, you will learn about what inventory management is, common inventory methods, and challenges faced by industries, along with the different types of inventory systems and more.

What is Inventory Management?

Inventory management is the systematic process of overseeing, tracking, controlling, and monitoring a company’s stock, including raw materials, and meeting customer demands. The goal of inventory management is to find a balance between the company’s supply of inventory and buyers’ demand for it.

What are the Common Inventory Management Methods

Common inventory management methods are diverse, and the best choice depends on a business’s specific needs and product types. Let’s explore some of the best inventory management methods:

1. First in First Out(FIFO)

FIFO is one of the most common ways to manage inventory i stock operations. This method makes sure the oldest items are used or sold first, which reduces the chance of the product going bad or becoming outdated. Businesses use this method for accounting because it gives a clear view of inventory levels and overall cost.

2. Last in First Out(LIFO)

LIFO is a way to calculate the cost of inventory when working out the cost of goods sold. This method treats the newest items added to inventory as the first item to sell out. In times of rising prices defines the gold sold carries higher costs as the latest stock is the most expensive. The method also helps in reducing taxes because businesses may deduct these higher inventory costs from their taxable income.

3. Just In Time(JIT)

Just-In-Time(JIT) inventory system is a system where businesses can order only the number of stocks that are required to fulfill the current customer needs. The method helps companies to reduce storage costs and make sure the product is always in stock when needed. Sometimes JIT can be risky during supply chain issues, so always make sure the business has strong order-tracking systems so you can respond quickly to unexpected delays.

4. Cycle Counting

This method helps businesses to confirm inventory accuracy by checking physical stock against recorded numbers. To do this task, companies run regular stocktakes and make updates for selected items. The methods offer several benefits like reducing the need for large annual counts, finding issues early and keeping inventory data accurate for better decision making. When carried out properly then this method becomes a valuable tool for effective inventory management.

Challenges Faced By Industries in Inventory Management

Industries face many challenges with inventory management due to several operational issues, market fluctuations, and complex global supply chains. The main issues involve keeping accurate data, matching stock levels with increasing demand, and utilising technology in the right manner. Let’s understand what the challenges face by industries:

1. Lack of Real-Time Visibility

Many business cannot track their stock across several locations or sales channels in real-time. Without this clear visibility, companies might face issues like stock mismatches, fulfillment mistakes, or lead to wrong decision-making.

2. Unreliable Demand Forecast

This remains a major issue for many companies. Poor forecasts cause overstocking, which leads to overspending, more storage space required, which leads to missed sales and an overall impact on unhappy customers.

3. Manual Process and Data Error

In modern times, many businesses still depend on traditional ways of managing inventory, like spreadsheets or paper, to track inventory. These ways of managing are slow and lead to mistakes. This results in poor data flow and unreliable stock information.

4. Warehouse Inefficiencies

Warehouse inefficiencies occur when the space is not organised well, and processes are unclear, which leads to slow order fulfilment and misplaced items. Poor utilisation of space also increases the risk of damage. These kinds of problems raise costs, reduce productivity, and make it complex for businesses to deliver orders on time.

5. Shrinkage of Inventory

The problem of Inventory Shrinkage occurs when the amount of stock does not match the actual need for stock. This often happens due to theft, damage or a simple error in counting. Shrinkage reduces the profit and creates problems in planning future stock needs.

Also Read: Choosing the Best Inventory Management Software Company in Singapore

What are the Types of Inventory Systems

Inventory management systems generally are of several types, which are used for a specific purpose. Let’s explore some types of inventory management as below:

1. Periodic Inventory System

The periodic inventory system offers a simpler, lower-tech option for businesses with smaller inventories. With this system, you can physically count your inventory at regular intervals like monthly, quarterly, or annually.

The periodic inventory system is a good option for many businesses that have limited resources or specific operational needs.

2. Barcode Inventory System

With barcode inventory software, each item is assigned a unique barcode that contains key information like product name, description, and price. When the barcode is scanned then the data is automatically logged into your inventory management software and updates your stock levels in real-time.

3. Perpetual Inventory System

The system gives users an exact inventory count without having to count manually or use a spreadsheet to count.

This approach uses technology to automatically update your inventory records every time a sale or purchase occurs.

4. Backordering

Backordering is a system where the seller accepts the orders for out-of-stock items and ships them when inventory becomes available. This is an optimised inventory management for SMEs as the system improves the cash flow and optimises storage space.

Backordering can help to manage short-term stock shortages or an unexpected rise in demand, but not a long-term solution.

Key Benefits of Inventory Management Software

Inventory management software offers several benefits that help to achieve huge cost savings, increase efficiency, and more. Let’s explore the benefits of Inventory Management Software below:

1. Reduced Cost & Improved Stock Levels

The software reduces operational costs by using automated stock suggestions along with the centralised inventory platform to maintain data and stock levels. As a result, regular stock counts, adjustments and transfers help to prevent unnecessary purchases. With inventory synced across all selling channels, companies can also avoid both overstocking and stockout, which ultimately leads to improved cash flow and resource allocation.

2. Better Customer Service

From a customer service perspective, the software must run faster, perform tasks quickly without delay. The system must be accessed by mobile and help in efficient packing & shipping processes. When inventory works effectively across all channels, customers take advantage of reliable product availability and timely deliveries. This leads to getting more loyal customers and achieving their expectations.

3. Scalability and Multi-Location Management

The platform supports growth effortlessly through features like multi-warehouse setup, bin locations, and seamless stock transfers between sites. As a business expands into new regions, location setup and reporting offer complete visibility across all areas of operation. Ultimately, this allows businesses to scale confidently without operational complexity.

4. Increased Operational Efficiency and Productivity

The system enhances day-to-day operations through automation, sorting, packing slips and shipping labels that streamline fulfillment. With this, the order moves smoothly from acceptance to picking and real-time shipment tracking, which keeps everything clear and organised.

Features like bin locations, user management, and multi-warehouse coordination help staff to work faster with fewer mistakes.

Why Business Trust Genic Solutions for Smarter Inventory Management?

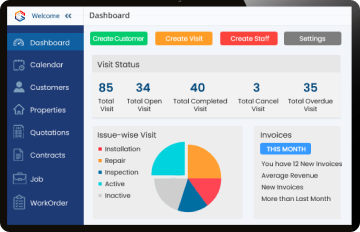

Businesses trust Genic solutions for their inventory management system needs because we at Genic solutions offer a reliable, user-friendly and highly efficient platform that centralises every aspect of stock control.

Our inventory system supports real-time tracking, automated updates, and seamless multichannel syncing that always helps businesses make better decisions. Our simple interface, best performance, and industry adaptability make us a trusted choice for businesses looking to reduce their operating cost and manage everything more effectively.

Core Feature of Our Inventory System

- Real-time inventory visibility and automated stock management

- Efficient order fulfillment with automated picking, packing, and shipping

- Simple Interface for faster, smarter decision making.

- Able to track multiple locations & channels with bin-level control.