Keeping stock organised has never been easy, and the strain on companies increases every year. The marketplace is continuously changing, the product lines are continually growing, and customers want seamless service, leaving very little room for errors.

A lot of teams are now being required to reconsider the way they manage stock, as a result of the increased demands upon them. That is the reason a lot of companies are relying on automated inventory management software in order to maintain their inventory.

It provides them with better insight into cleaner processes as well as better control of their daily operations. Teams are able to make fast and self-confident decisions, rather than juggling spreadsheets or newspaper notes, as stock changes occur.

Businesses can remain competitive in a fast-paced market, and automated tools are able to save time, minimise errors and boost efficiency. Stock control becomes a lot more effective, easier to scale, and simpler to manage with dependable systems set up.

Why Smarter Stock Control Matters Today

Manual Tracking No Longer Works

Old stock control often relied on paper logs, spreadsheets, and guesswork. These methods lead to errors, delays, and confusion across teams. With more items to track and customers expecting quick fulfilment, companies see the limits of manual work.

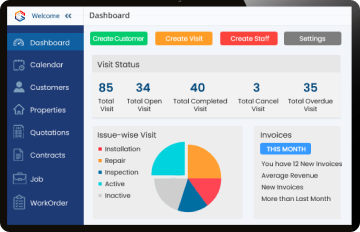

This is where automated inventory management steps in. It speeds up stock updates, removes repeated tasks, and shows what is happening in real time. Staff can see stock levels the moment they change, so they can act right away.

The Rise of Digital Operations

More companies now run online stores, manage large product lines, or trade across borders. They need tools that keep pace with this flow. Automated inventory systems support these needs by giving a single place to view, track, and manage stock across stores, warehouses, and channels.

As more teams move to digital-first operations, stock control becomes easier, faster, and more reliable.

Why Businesses Prefer Automated Inventory Tools

1. Clear Stock Accuracy

Human error is the main cause of stock issues. Mistyped numbers, skipped updates, and lost notes create confusion. With automated inventory software, updates happen the moment items move. This reduces stock mismatches, lost sales, and customer complaints.

Accurate stock data helps teams plan better. They can reorder at the right time, avoid shortages, and keep the right level of supply.

2. Better Use of Time

Staff spend large parts of their day checking stock, counting items, and fixing errors. Automated inventory control platforms take over these tasks. The team can then focus on growth, customer service, and planning instead.

This shift cuts workloads, boosts output, and brings more value to the business.

3. Improved Cash Flow

Stock that sits unused ties up money. Overstocking wastes space and cash. Stockouts lose sales and harm trust. With inventory management software, companies can track trends and predict needs. They buy what they need at the right time.

Better stock planning leads to less waste, more sales, and stronger cash flow.

4. Strong Insight for Decision-Making

Good stock decisions come from good data. Automated tools show patterns such as best-selling products, seasonal shifts, and slow-moving items. With clear insight, companies adjust stock levels, change suppliers, or replace weak items.

Leaders gain a clearer view of the business and can plan with more confidence.

5. Smoother Team Collaboration

Merchandising, operations, purchasing, and sales all rely on stock information. When this data is out of sync, teams clash. Automated systems offer one source of truth that everyone can access.

This shared view reduces miscommunication and helps each team work with up-to-date information.

Read Also: Inventory Management System Software: What It Is & How It Works

How Automated Inventory Tools Change Daily Operations

Faster Order Processing

When stock data updates on its own, orders move through the system with less delay. Teams no longer need to check stock by hand before confirming an order. This creates a smoother buying process and happier customers.

Better Control Over Warehouse Operations

Warehouses run better when stock is easy to find and track. Automated inventory management tools help teams organise items, label zones, and reduce picking mistakes. This keeps the warehouse tidy and helps staff work faster.

Real-Time Alerts and Tracking

Being warned early saves time and money. Automated tools can send alerts when stock runs low, when demand rises, or when sales shift. These early signs help avoid stockouts and rushed orders.

Support for Growth

As a business grows, stock numbers rise. Manual systems break under pressure. Automated inventory systems scale with the business. Whether one store or ten, the process stays smooth.

The Role of Inventory Management in Today’s Market

Customer Expectations Are Higher

Online shoppers expect fast delivery and accurate stock details. If a product shows as available but is not, customers leave. Good inventory management prevents this by keeping stock updates in sync with the shop front.

Supply Chains Are More Complex

Today’s supply chain is global. Shipping delays, supplier shifts, and cost changes happen often. Companies need clear data to respond. Automated inventory tools support these changes with steady insight and fast updates.

Competition Is Fierce

Many markets are crowded. To stay ahead, companies must run lean operations and reduce waste. Automated stock tools help them stay organised and competitive.

Also Read: Next‑Generation Inventory Management: AI, IoT & Automation

Choosing the Right Automated Inventory Tools

Look for Clear, Simple Features

A good system should be easy to use. Staff must be able to learn it without long training sessions. Clear dashboards, simple controls, and steady updates make a huge difference.

Make Sure It Fits Your Stock Needs

Different businesses track different items. Some need batch control, serial numbers, or multi-location tracking. Others need support for bundles or kits. Pick tools that match your stock type and workflow.

Check Flexibility for the Future

A system might work now, but fail later if it cannot scale. Look for tools that grow with the business. This stops the need for another system switch later.

Consider Integration with Other Tools

Many companies use finance, sales, or warehouse tools. Your inventory system should connect with these. This keeps data consistent across departments.

Why Companies Also Look at Inventory Management Software Providers

Many businesses also explore inventory management software options and compare inventory management software companies. The aim is to pick solutions that support long-term plans. These providers help teams set up systems, guide them through best practices, and offer help when the business grows.

Good partners understand stock challenges across different industries. They support companies by offering flexible systems and steady improvement.

The Future of Automated Stock Control

Smarter Forecasting

Automated stock tools will soon offer sharper insights into buying trends and product demand. They will spot patterns early, guide teams on what to reorder, and reduce waste. This helps businesses keep the right stock at the right time.

Stronger Supply Chain Links

Future systems will link suppliers, warehouses, and sales channels in one smooth flow. With real-time updates, teams will respond faster to delays, shortages, or sudden spikes in demand. This gives greater control and steadier stock levels.

Easier Scaling for Growing Brands

As businesses grow, their stock needs change. New automated tools will scale with them without slowing operations. They will support more products, more sales channels, and more warehouse locations with ease.

Clearer, Faster Decisions

With improved insight and steady data, leaders will make quicker, stronger choices. Automated stock control will become the base for stable growth and smooth daily work.

Also Read: Best Inventory Software Tools for Businesses in 2026

Final Thoughts

Automated inventory tools are becoming very popular since they offer companies greater precision, speed, and clarity. These systems get rid of time-consuming tasks, support better planning and reduce manual errors.

Additionally, they help to avoid stockouts, bring down waste and also enhance the flow of everyday operations. Reliable stock control is crucial as the intricacy of supply chains grows, as well as customer expectations increase. The obvious benefit for companies using automated tools is the fact that they could offer real-time insight into their business and create a solid long – term foundation.

The trend towards smart stock control continues to develop, from automatic inventory management systems to far more advanced automated inventory software products. People who use these tools early on create better processes, boost performance and make room to scale confidently.