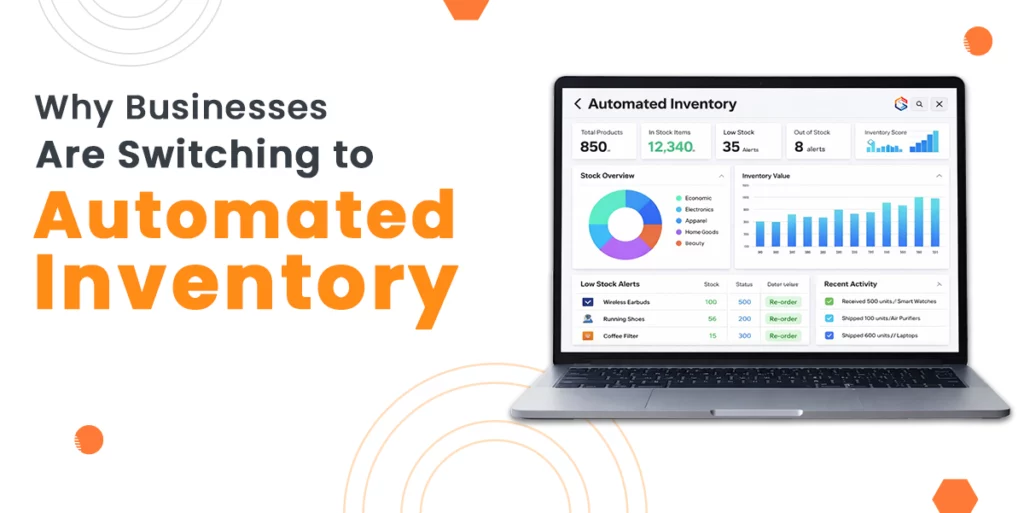

An inventory management system is a process of managing, tracking, ordering and selling the raw materials of the company’s stocks.

Nowadays, the traditional method can’t handle the complex supply chain and growing customer demand. That’s where next-generation technologies like artificial intelligence, Internet of Things(IoT) and automation come in. With the help of these technologies, the inventory management system becomes more reliable, faster, and smarter.

In this guide, you will learn about how these technologies transform the traditional inventory management system into an efficient, responsive system for modern business, along with the benefits of integrating each technology and more.

What is Inventory Management?

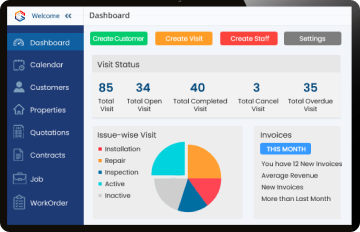

Inventory management is the process of overseeing and controlling a company’s inventory from raw materials to finished goods. Modern inventory management system software can range from simple tools for small businesses to advanced software for large-scale businesses. With the rise of warehouse automation for small and medium businesses, the ability to scale inventory operations has become more accessible than ever.

How does Next‑generation Technology Transform Inventory Management?

As a business grows day by day, the supply chain becomes more complicated, so the industry needs a such inventory system which is faster, smarter and self learning. Let’s understand how these technologies strengthen the inventory system operations in unique ways:

1. Artificial Intelligence in Inventory Management

The AI uses powerful algorithms along with various machine learning models to handle large amounts of business data and find insights that people might normally miss.

These system don’t just predicts, but they use real-time data to give clear and helpful answers. With Inventory management AI, businesses can match their stock with the customer demand, avoid delays and keep shelves full without overstocking.

AI-based systems keep learning and updating over time. They adjust according to the market fluctuations, supply chain behaviour and shifting customer behaviour which makes them ideal for AI demand forecasting for inventory management systems.

2. IoT in Inventory Management

Managing inventory has always been challenging in business, whether in a retail store, a warehouse that misplaces stock, or a manufacturing unit whose production is delayed because certain materials are missing.

This is where the IoT inventory tracking came into the picture and handles things very smartly. IoT is not just simple tracking technology, but it’s a way to know where your inventory is and how it’s moving.

By integrating IoT and AI in inventory control software, you can reduce operational inefficiencies, grow visibility into the stock levels and prevent big mistakes.

3. Automation in Inventory Management

Automation uses technologies like software and robotics to execute tasks or processes with minimal human interference.

Automation helps inventory management by replacing manual and time-consuming tasks with technology-driven processes.

Manual inventory processes are prone to human error, which leads to costly mistakes like misplacement, inaccurate count of items and shipments. But with an automated inventory system, it eliminates manual entry where most problem occurs.

Also, many companies are now evaluating the cost vs ROI of inventory automation for SMEs to understand how automation can improve accuracy and speed up operations while staying budget-friendly.

Benefits of Integrating AI in the Inventory Management System

AI helps businesses to do more tasks with less effort. AI help the inventory system to improve accuracy, reduce time and boost productivity. Below are the benefits companies can bring to their campus by using an AI-enabled system:

- Better Decision Making: An AI-enabled system helps in better decision-making by analysing data to make automatic and accurate decisions. It predicts what, when and how much is needed using a cloud inventory system with AI insights.

- Improved Customer Experience: AI-enabled system ensures the customer will get the product when they need it. It improves delivery time, customer trust and order accuracy. It helps the brands to build strong and reliable relationships with their buyers.

- Predictive Maintenance: Sensors, like conveyors and forklifts, are integrated into warehouse management which feed data into the AI system that can predict maintenance needs.

- Seamless Adaptability: As your business expands and AI can scale with it. The system handles more data, tracks multiple locations and adapts to sudden changes in demand or supply.

Benefits of Integrating IoT in the Inventory Management System

The Internet of Things plays an important role in inventory tracking. Let’s explore some of the best benefits of integrating IoT into the inventory systems:

- Real-time Inventory Tracking: IoT shows businesses a live view of their stock as where it is located, how much is left, and if it’s kept safely. GPS trackers follow deliveries, and sensors in storage check the temperature and air. This protects the products and helps teams plan, avoid delays and stay ready with the right stock.

- Error Reduction: Manual stock tracking often leads to mistakes like misplaced items or lost stock. Integrating IoT with the inventory system will overcome it. With tools like RFID tags and barcode scanners, everything gets tracked automatically. This reduces human errors and ensures accurate data by making decision-making much easier and more reliable.

- Cost Savings: IoT helps reduce costs by keeping inventory levels just right. It prevents both overstocking and running out of stock, which saves on storage space and staff time. It also improves how resources are used in the warehouse, reducing waste and making order handling much more efficient.

- Geofencing: By using the geofencing feature of IoT protect your shipment when it arrives at a specified location or moves outside the desired location which helps to prevent theft.

Benefits of Integrating Automation in the Inventory Management System

Automation helps the inventory management system in various ways. Let’s explore its benefits below:

- 24/7 operation: Unlike humans, automated inventory systems can operate whole time. This is especially beneficial during peak seasons or for e-commerce businesses with a large number of orders.

- Faster order fulfilment: Automation tools like robots and smart machines can find, pick, and pack items much quicker than people. This speeds up the order process, helping businesses ship products faster and keep up with high demand especially during busy seasons.

- Better forecasting: By collecting accurate, real-time data, automation provides the foundation for advanced analytics and demand forecasting tools, which help businesses fulfil future needs with higher accuracy.

- Improved Accuracy: Automation replaces manual tasks like data entry or physical counts, which often lead to mistakes. With tools like Automated scanners and tracking software, inventory gets updated automatically. This ensures real-time accuracy which reduces errors and helps teams trust the data when making decisions.

- Reduce Labour Dependency: Robots can take over routine tasks, which helps humans to focus on decision-making and value-added operations.

How Do These Technologies Work Together?

The combination of Artificial Intelligence, Internet of Things, and Automation builds a smarter inventory management system. Let’s see how they work together and give better results:

Step 1: IoT Collects Real-Time Data

IoT devices like sensors, scanners, and trackers gather, watch, and follow your inventory across warehouses and supply chains. They spot where items are located, check the temperature and track movement, giving real-time updates.

Step 2: Analyse the Data

After IoT sends the data. The AI uses data and applies smart machine learning to spot patterns, guess what’s needed, catch mistakes, and give suggestions. This helps teams decide things faster and better by using real-time data.

Step 3: Automation

Now the role of automation will start. The automated software picks, packs, restocks, or orders items all without human interference.

Step 4: Continuous Improvement

AI keeps learning from every step. It grows smarter, while IoT keeps sharing real-time data and automation keeps moving. Together, they built a self-learning, advanced inventory system.

What SMEs Should Know Before Investing?

Every SME should know before investing in the next-gen inventory management system, as defined below:

1. Define Strategy

Before investing, understand your business problems and can AI, IoT and automation can help improve your inventory accuracy, speed up customer support. So start with the main problem to solve.

2. Choose a Relevant Tool

Looking for affordable, accessible, easy-to-manage no-code tools. These tools scale your business without much cost.

3. Train your Team

Give training to your team about how the tools work and make their work easier. A Smart team drives innovation and maximises productivity.

4. Monitor and Adapt

Continuously monitor the performance of the process and get feedback from the employees and the client. Update your approach according to business needs and market changes.

Future of Next Gen Inventory Management System

As the digital transformation expands across every industry, the inventory management system will continue to evolve with more capabilities. Those businesses will invest in these technologies will get higher speed and stronger control across the supply chain.

1. AI and machine learning advancements

Artificial intelligence and machine learning will continue to evolve from simple predictive models to more sophisticated decision-making systems.

2. Improved Fraud detection

AI will analyse inventory movement patterns and real-time security footage to find anomalies which help to identify and prevent theft or fraud.

3. Omnichannel fulfilment

The inventory system will better support models like buy online pickup in store(BOPIS) to meet customer expectations for speed and transparency.

4. Circular inventory models

To reduce waste and save the environment, the business will adopt a circular model system which focuses on reusing, recycling and reselling of products.

5. Smart shelves

These IoT features will weigh sensors and RFID readers to automatically detect low stock levels, triggering alerts or automated reorder processes without manual counting.

Conclusion

Overall, the future of inventory management software is based on how you adopt advanced technology into your existing system for day-to-day operations. These advancements help you to improve accuracy, productivity.

As the number of users increases exponentially, the data becomes very large and businesses need a system which can handle a large volume of data easily, so this can be achieved by applying these AI, IoT and Automation technologies.

At Genic Solutions, you’ll find a powerful inventory management system software designed to simplify stock control, boost accuracy, and scale with your business.