Inventory management is one of the most important parts of running a small business, but it’s also one of the easiest areas to get wrong. As sales channels expand and customer expectations grow, managing stock with manual methods becomes difficult very quickly.

From forecasting demand and controlling variants to keeping accurate counts across locations, every stage adds complexity that small teams struggle to handle alone. These are the most common inventory challenges SMEs face, and when systems fail, delays, overselling, and wasted cash start affecting your daily operations.

That’s why understanding the key challenges and knowing how to apply inventory management best practices is essential for keeping orders moving smoothly, protecting profit, and staying competitive in any market.

Why an Inventory Management System for Small Businesses Is Important

An inventory management system for small business must be simple to use, but it must also support the growing demands of daily operations. For most SMEs, managing stock manually becomes difficult very quickly.

As orders increase, channels expand, and customer expectations rise, the old methods of spreadsheets and guesswork can no longer keep up.

From real-time stock visibility and accurate order tracking to managing multiple locations, reorder levels, and fulfilment timelines, these needs add layers of complexity that basic tools can’t handle on their own.

When small businesses don’t have a proper system, delays, overselling, and unexpected stockouts become common, which affects both cash flow and customer trust.

Inventory Management Challenges for SMEs

1. Forecasting Inaccuracy

Forecasting is not just predicting what customers may buy, but it also helps to decide how to manage cash and how to keep orders moving.

Demand changes anytime. Promotions, seasons, delays and shifting customer habits make it hard to know what stock you will need soon or next quarter. Many teams depend only on past sales and ignore what is changing right now.

This leads to either having much of the wrong stock or too little of what customers actually want.

How to Solve Them

- You can use smarter forecasting tools that help more than spreadsheets. As forecasting applies machine learning models to get insights from trends, seasons, and marketing activity.

- Instead of combining all sales, you should look at each channel, like DTC, wholesale, or retail. Each channel works differently, so dividing them makes it easier to plan a stock for the right place.

- Sales help you know where deals are coming from. But marketing knows which campaigns will increase demand. When these teams share updates, your forecast becomes more accurate.

2. Lack of Real-time Visibility

Poor visibility of stocks is one of the most common and costly issues in ecommerce because businesses can clearly see where all their stock is.

When you don’t have an accurate view of inventory over every location and stage, then the fulfillment of terms will slow down, overselling happens, and in the end, customers end up disappointed.

These gaps usually come from a disconnected system, missing information or inconsistent tracking.

How to Resolve This

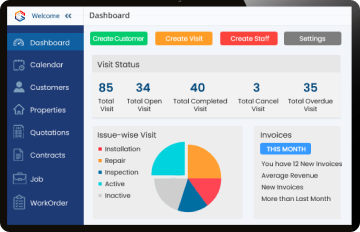

- Use software that gives you clear visibility on every location so you can see on-hand, in-transit, and reserved stock in one place.

- Sync systems so everyone uses the same real-time inventory data. So when you connect your system with ERP or WMS, then you can keep your data unified so every team works from the same accurate data.

- Visibility is more than just quantities, as it means identifying delays and mismatches before they affect business

Also Read: Inventory Management Systems: Key Features & Benefits for SMEs

3. SKU Overload and Inventory Chaos

SKU proliferation happens when adding too many product variations creates more problems than benefits. As the range grows, every new item becomes another SKU to track, store, predict, and ship.

If the SKU count shows more than your system can handle, then accuracy may go down, and operations get messy. Inventory counts take longer, and stock mistakes increase.

Stock checks start taking more time, inventory errors rise and doing reorder points becomes unreliable, and warehouse teams end up wasting time searching for items instead of getting orders out the door.

How to Fix

- Regularly review your SKU performance by identifying slow, low-margin products and removing them when they are not worth to keep it.

- Try to group similar variants by rolling up sizes or colours under a parent SKU or style code, which makes stock tracking easier.

- Create a clear SKU rule that defines who can make new SKUs, how they are named, and tracked, so growth does not turn into operational clutter.

4. Issue with Meeting Compliance Standards

An inventory management system for small business must be efficient, but it must also meet the compliance demands. For sectors like food, cosmetics, and other regulated goods, these rules are no longer essential.

From accurate labelling and IoT tracking to temperature check, expiry controls, and strict documentation, which adds complexity to most standard inventory control systems that can’t be handled on their own.

How to correct it

- Use an inventory system designed for compliance by choosing tools that automate IoT numbers, expiry dates, audit logs, and tracking details so you don’t have to manage them manually.

- Find the exact regulations for your industry by understanding the rules for your product type and location, then shaping your workflow around those specific requirements.

- Run internal audits before external ones by regularly checking your documentation and strange conditions to catch and fix issues early.

- Train more than the warehouse team by ensuring everyone involved in the supply chain understands the basic compliance rules, not just staff on the warehouse floor.

5. Manual Tracking Systems

Many ecommerce businesses depend on spreadsheets and paper notes to manage inventory controls, but this setup only works for short durations.

As the volume of data increases the every update becomes another manual entry to type, double-check and expect no one will overwrite it.

When the process can’t keep up, then accuracy and operations become difficult to manage. This makes stock counting take a longer time, might errors in data, and more.

When something goes wrong, you need to go through a large amount of data in a spreadsheet to understand what went wrong, while the orders back up and errors keep rising.

How to Solve Them

- Adapt a proper inventory management system for a small business. Because even a lightweight cloud tool with barcode scanning, real-time syncing, and an audit log is a major upgrade over Excel.

- Give training to the team about how to enter data clearly and consistently. Poor documentation leads to poor decisions.

- Automate recurring tasks like reorder points, receive logs, and adjustments so the system handles routine updates, not your workforce.

Read Also: Inventory Management System Software: What It Is & How It Works

6. Cash Flow Constraints

An inventory system for a growing business must track stock accurately, but it also needs to determine the full cost behind every item you have. For most SMEs, these unhandled expenses are no longer essential, but they are still important to handle them efficiently.

From storage handling to shipping, return, and even the capital tied up in goods that don’t sell, these added costs create complexity, which signifies that basic tracking alone can able to manage.

How to Fix This

- Track total landed cost, not just the unit price, by including shipping tariffs and handling, so you get a real idea of what each product costs you.

- Review warehouse layout and workflow by checking slotting, choosing routes, and space use so labour time and error don’t keep rising unnoticed.

- Monitor carrying costs every month by reviewing storage, shrinkage, insurance, and depreciation to uncover problems before they turn into financial loss.

Conclusion

Inventory challenges for SMEs are also signs of where your systems need improvement. When you solve these issues with the right tools, clear workflows, and accurate data, operations become faster, stock becomes easier to control, and costly mistakes start to disappear.

A proper inventory management system helps you avoid overselling, manage variants, handle compliance, and control costs without relying on spreadsheets. More importantly, it supports fixing stock issues by keeping processes stable as order volumes rise.

By addressing these challenges early, small businesses can build stronger operations, improve customer satisfaction, and stay ready for every new opportunity ahead.

At Genic Solutions, you get real-time visibility, automation, and accurate tracking that replace messy spreadsheets with reliable inventory control.